- Home Page

- Company Profile

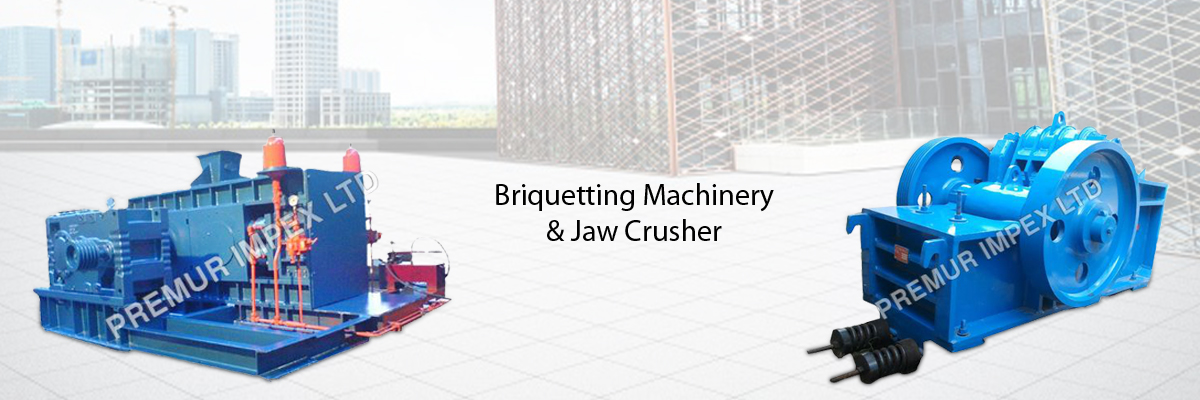

- Our Products

- Extra Links

- Our Customers

- Contact Us

MixerOur company offers high speed Mixer that can be used in small to large scale industries such as food, pharmaceutical, chemical, cosmetic and many more for the mixing of large volume of powdered, granular as well as solid ingredients to make a fine and uniform paste. The structural frame of these machineries is made up of engineering class materials that make them capable to withstand large vibrational forces produced during the operation. These Mixer are available in single as well as double pan designs as per clients requirements. They are equipped with high performance electrical motor that make them capable to make mixture with a capacity in between 500 to 2000 Kilograms per hour. |

|

|

|

|

×

Add a mobile number to receive call from "PREMUR IMPEX LTD."

×

Enter OTP

×

Share additional details for a quick response

×

Thank You!

Thank You for your valuable time. We have received your details and will get back to you shortly.

×

Get a price quote for Single Pan Mixer

×

Our Location

Products Gallery

Contact Details

- 10, 1st Floor, Burnt Salt Gola Lane, Howrah - 711101, West Bengal, India

- Phone : 08045816926

- Mr B Chakraborty (Director)

- Mobile :08045816926

- Send Inquiry

PREMUR IMPEX LTD.

An ISO 9001 : 2015 Organisation

An ISO 9001 : 2015 Organisation

PREMUR IMPEX LTD.

All Rights Reserved.(Terms of Use)

Developed and Managed by Infocom Network Private Limited.

Developed and Managed by Infocom Network Private Limited.

✕

Contact Us

Name

Comapny Name

Phone Number

Email Id

City / State

OTP Verification

Verification Code

Did not receive yet?

Resend OTP

Thank you!

We have received your requirements

For an immediate response, please call this

number 08045816926

✕

Tell us about your requirement

Price:

Quantity

Select Unit

Additional detail

Mobile number

Email

Name

Comapny Name

Phone Number

Email Id

City / State

Confirm Your Requirement

Verification Code

Did not receive yet?

Resend OTP

Youre Done!

We have received your requirements and will reply shortly with the best price.

Products You May Like