- Home Page

- Company Profile

- Our Products

- Extra Links

- Our Customers

- Contact Us

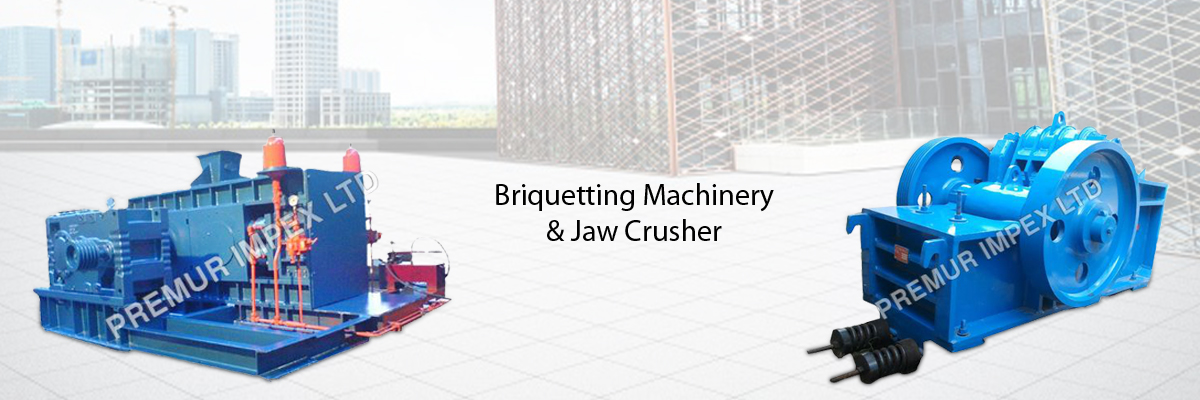

Jaw CrusherJaw Crusher are especially designed compression type heavy engineering tools that are comprised of a fixed jaw and moving jaw positioned in a V-shape. They works moving the movable part which compresses the materials against the fixed jaw to crush them to the desired size and then discharged through the bottom opening after processing. Jaw Crusher are equipped with a heavy flywheel which rotates the constituent parts for the efficient functioning of the machinery. These industrial devices weighs around 4 to 5 tonne with an excellent working capability.

|

|

|

|

|

×

Add a mobile number to receive call from "PREMUR IMPEX LTD."

×

Enter OTP

×

Share additional details for a quick response

×

Thank You!

Thank You for your valuable time. We have received your details and will get back to you shortly.

×

Get a price quote for Double Toggle Jaw Crusher

×

Our Location

Products Gallery

Contact Details

- 10, 1st Floor, Burnt Salt Gola Lane, Howrah - 711101, West Bengal, India

- Phone : 08045816926

- Mr B Chakraborty (Director)

- Mobile :08045816926

- Send Inquiry

PREMUR IMPEX LTD.

An ISO 9001 : 2015 Organisation

An ISO 9001 : 2015 Organisation

PREMUR IMPEX LTD.

All Rights Reserved.(Terms of Use)

Developed and Managed by Infocom Network Private Limited.

Developed and Managed by Infocom Network Private Limited.

✕

Contact Us

Name

Comapny Name

Phone Number

Email Id

City / State

OTP Verification

Verification Code

Did not receive yet?

Resend OTP

Thank you!

We have received your requirements

For an immediate response, please call this

number 08045816926

✕

Tell us about your requirement

Price:

Quantity

Select Unit

Additional detail

Mobile number

Email

Name

Comapny Name

Phone Number

Email Id

City / State

Confirm Your Requirement

Verification Code

Did not receive yet?

Resend OTP

Youre Done!

We have received your requirements and will reply shortly with the best price.

Products You May Like